A guide to hydraulic pump maintenance

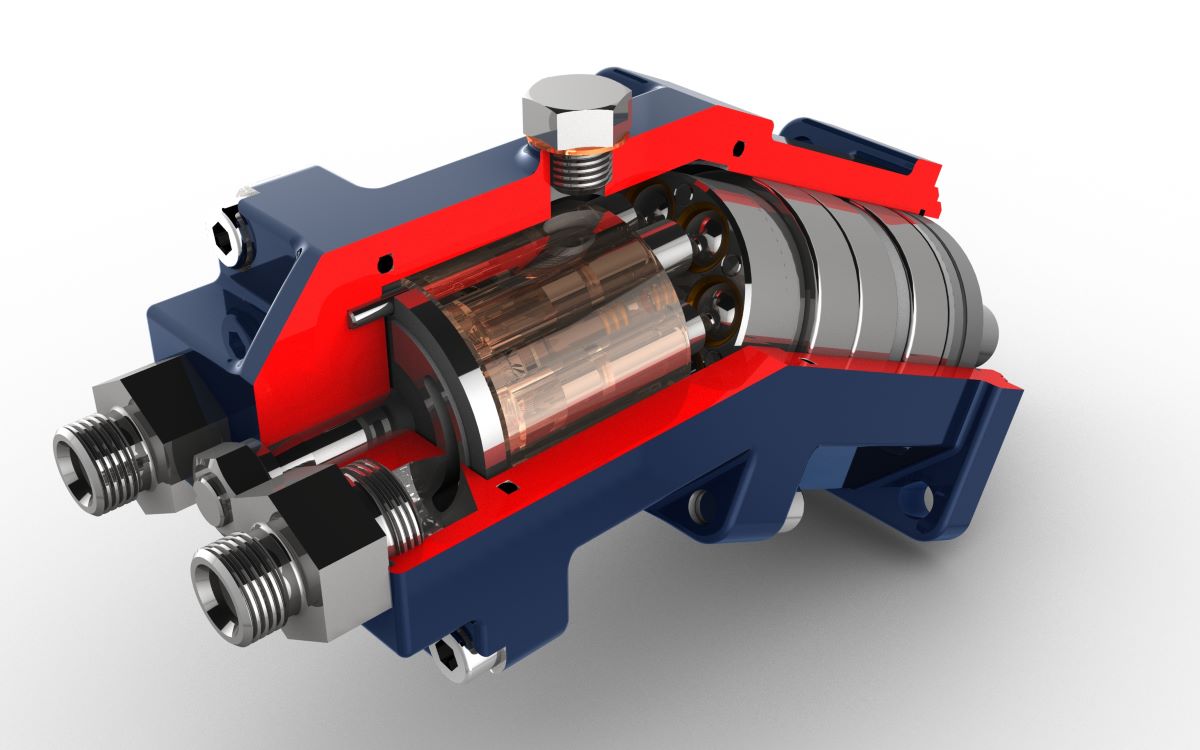

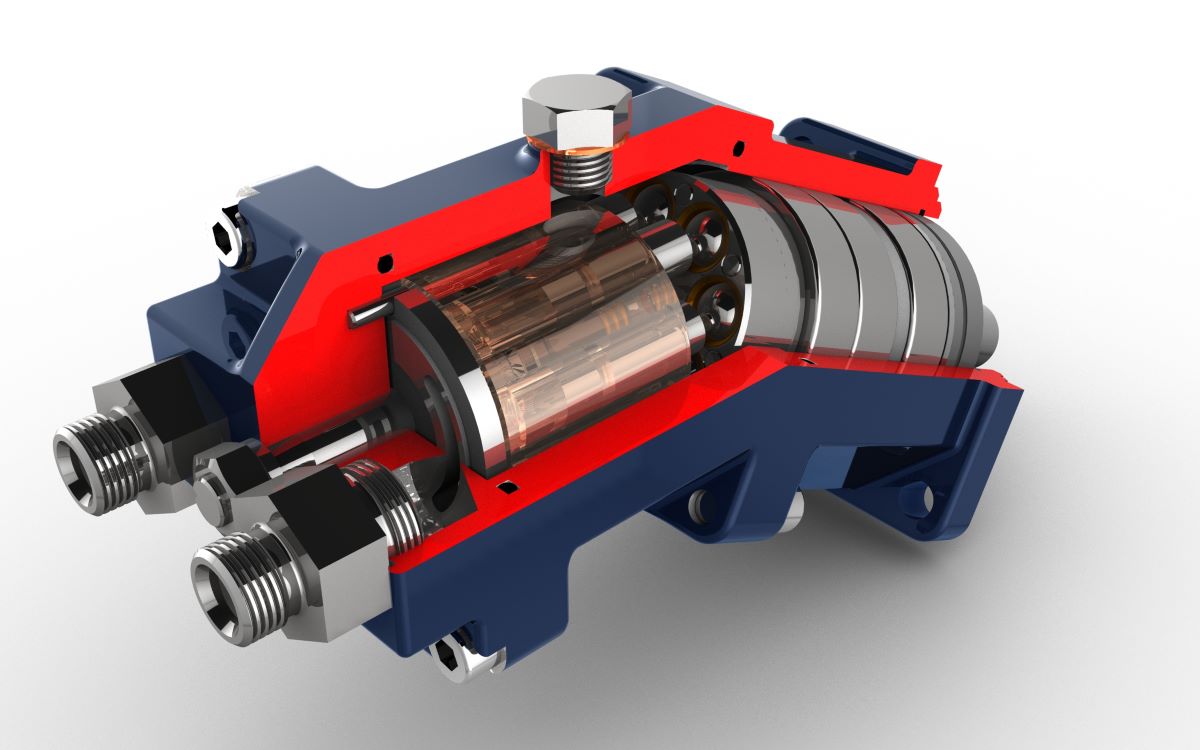

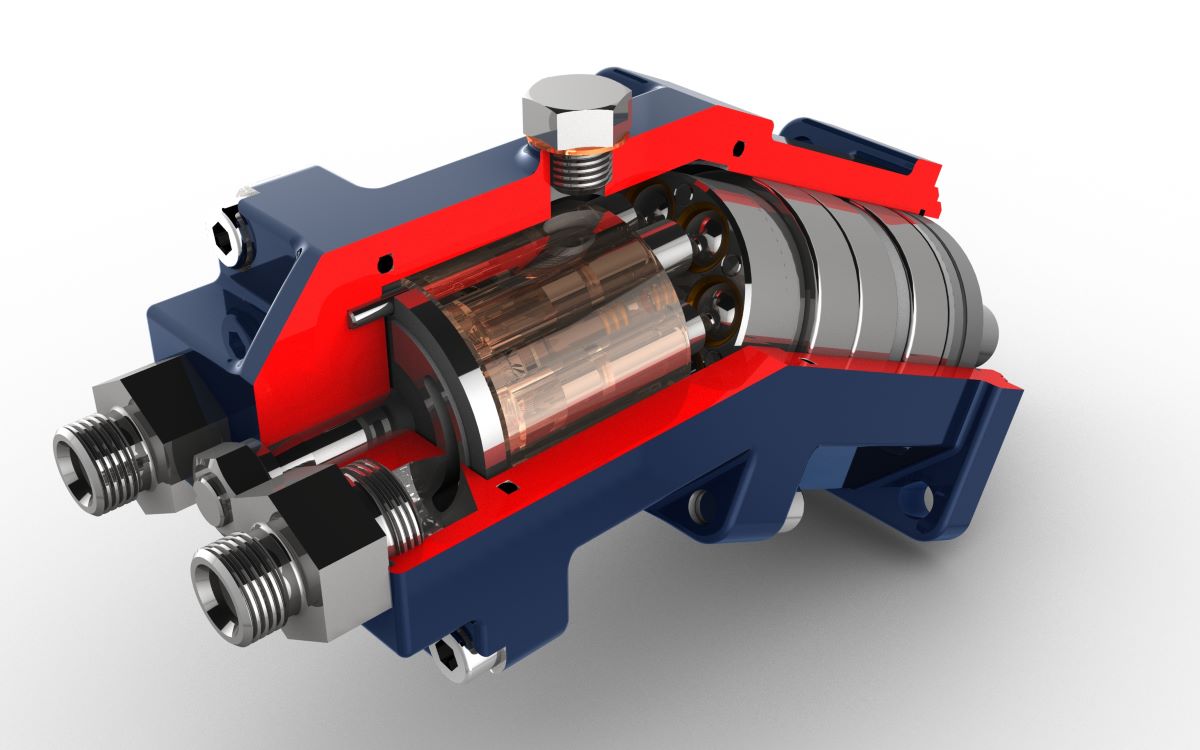

Hydraulic pumps are integral to the operation of any hydraulic machinery, responsible for converting mechanical power into hydraulic energy.

The failure of a pump is often one of the main reasons for a breakdown in a hydraulic system, therefore performing preventative maintenance is key to helping your equipment last longer.

Over time, hydraulic equipment is susceptible to breaking down but with proper care and maintenance, it should serve you for years to come.

If you want to get the most out of your hydraulic pump, here are a few maintenance tips to keep on top of.

1. Check the hydraulic fluid levels

Hydraulic fluid is critical to the smooth operation of the pump, so it’s important that correct fluid levels are kept in check at all times.

Pump manufacturers typically specify a fluid change schedule, which dictates how often the fluid has to be changed depending on how many hours the pump has been operational. Take note of how long the pump has been in action, and work out when the fluid level in the reservoir needs to be checked. If you’re unsure, a general rule of thumb is that the oil level should usually be at ½ inch from the top of the indicator.

Failure to maintain consistent fluid levels can prevent the pump from building enough pressure, which often leads to it drawing air into the reservoir and causing issues such as cavitation.

It goes without saying that you also need to be using the correct type of hydraulic fluid for your system, and make sure the levels of contamination are not such that the system will be damaged. Contamination can have huge impacts on the pump and other components in the system, so the following checks will help to prevent this.

2. Keep the suction strainer clean

Every hydraulic pump tank has a suction strainer which helps to keep debris at bay. Ensuring the strainer is clean and fully functioning is integral to the overall efficiency of the system which can control the levels of contamination.

Remove the suction strainer according to the manufacturer’s instructions and follow the cleaning directions before re-installing it back into the tank.

3. Regularly change hydraulic filters

Similarly, all other hydraulic filters within the system should be checked frequently to ensure they are effectively removing debris from the fluid.

Filters will typically have a specified schedule that dictates how often they should be changed, depending on the number of hours they have been in operation. The longer a filter sits in a system, the less effective it becomes as it starts to clog up.

It’s wise to put a filter changing schedule in place to ensure they are helping to control the contamination correctly at all times.

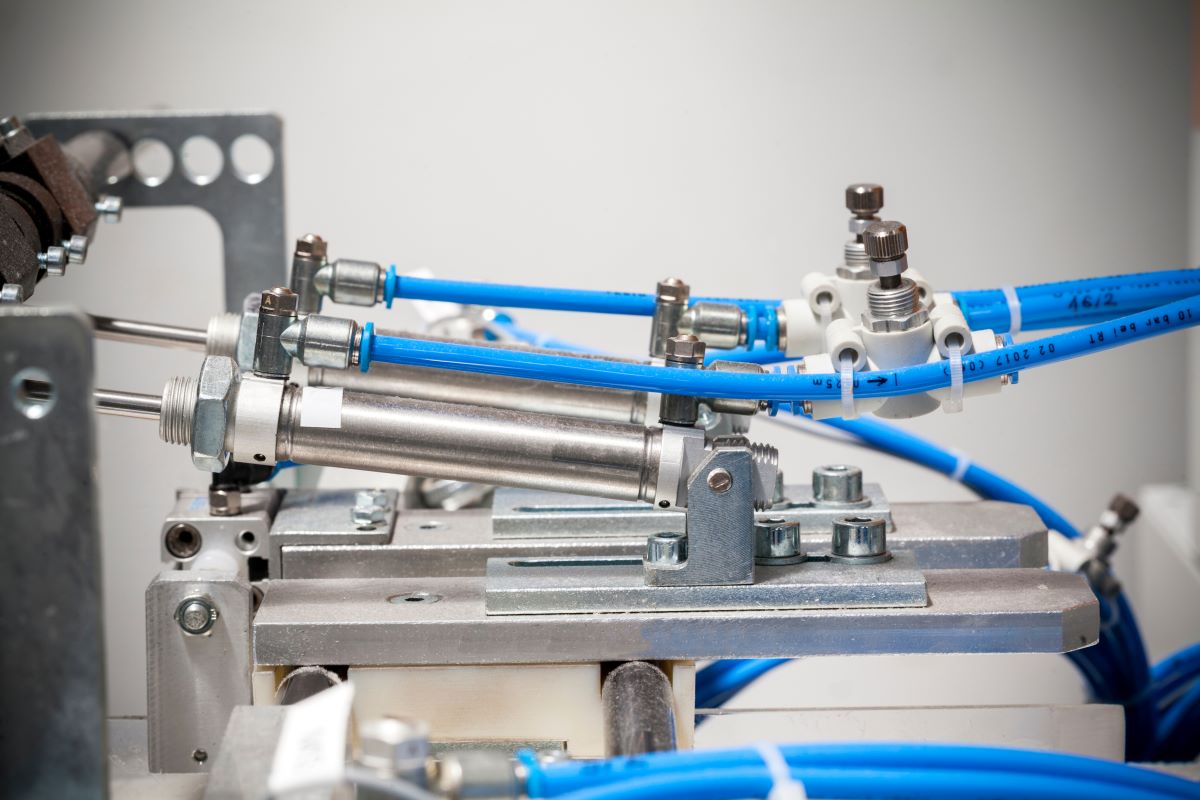

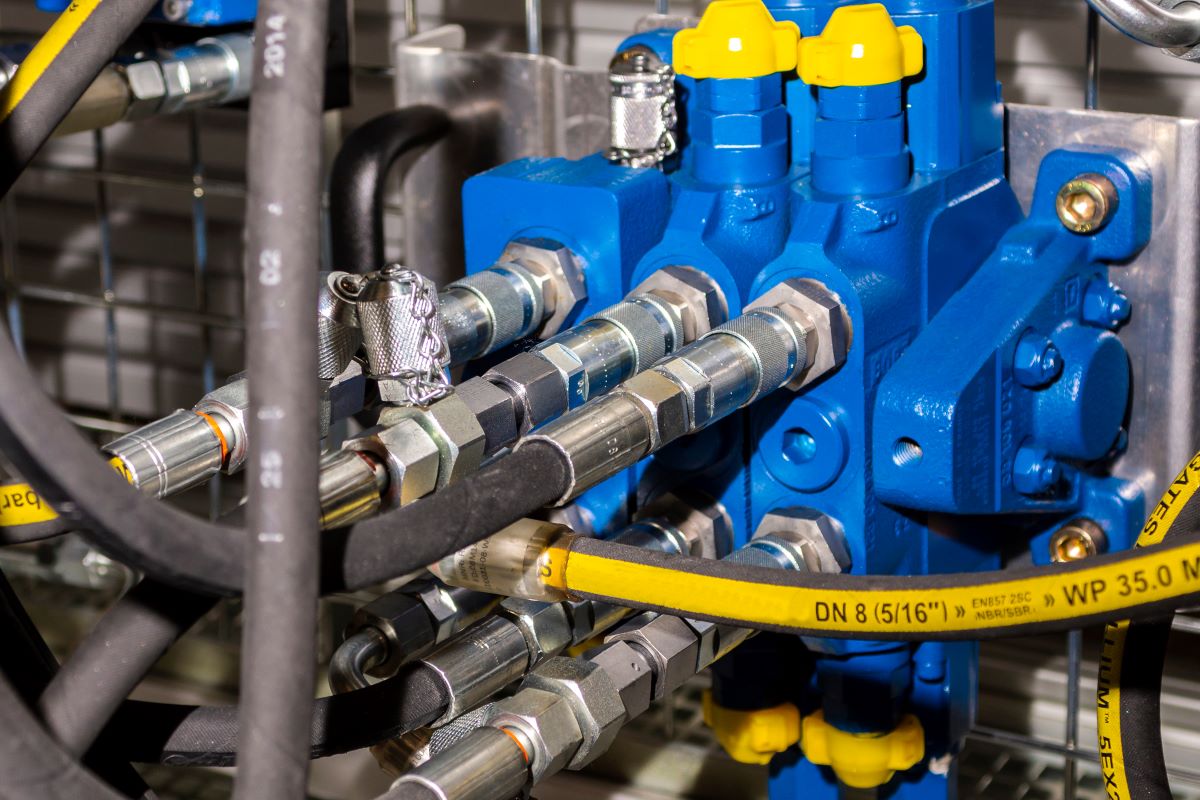

4. Visually inspect the hose and connections

Any good pump maintenance schedule should include a visual inspection of the hydraulic hose and its connections to the pump.

Hoses are susceptible to cracking, bending and twisting which can impact the fluid flow and therefore the pressure of the pump. Check for any visible signs of wear, damage or any potential internal issues, and inspect the couplers, fittings and pipes to ensure they are functioning properly and fitted accordingly.

5. Clean the pump’s exterior

Ensuring that the pump exterior and all connecting equipment are kept as clean as possible is just as important as cleaning the interior. This should be done before removing the pump interior in order to limit any contamination going inside the pump.

6. Stick to a regular maintenance schedule

Hydraulic pump maintenance is one of the most effective ways to keep your equipment working efficiently, but it must be conducted regularly and thoroughly.

It’s recommended to perform the above tasks at least once per month, and ensure that all of your operators are aware of what should be done and when. This way, you have the best chance of identifying any possible issues, and rectifying them before it’s too late.

For the most part, preventative maintenance can be done in-house but when it comes to any changes or modifications to your equipment, these should be dealt with by a skilled and qualified engineer.

If you’re looking for a reliable hydraulic components partner, get in touch with Primary Fluid Power. We have access to 1000’s of individual components and can build or modify equipment to meet your exact needs – whether it’s a shaft change on a pump or a coil change on a valve. Our team of fluid power experts can advise on the most suitable option for you.